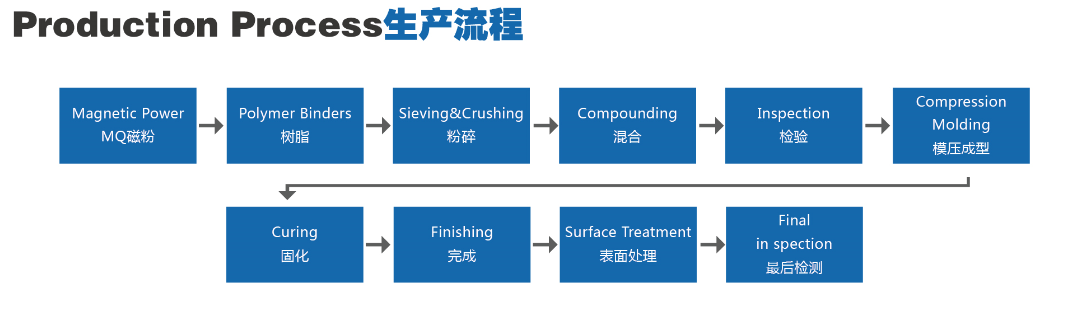

Typically, bonded NdFeB magnets are produced by compression molding of composite materials

NdFeB alloy powder and epoxy resin, also can be made by injection or extrusion

NdFeB alloy powder mixed with plastic. Features are as follows: High magnetic

Product shape freedom, high dimensional accuracy: good corrosion resistance

Resistance: After electrodeposition or other special treatment, diversified magnetization:

High production efficiency, suitable for mass production.

Proprietary technology and advantages

●Specializing in the production of various high-precision, complex-shaped adhesive parts

NdFeB magnets;

●Professional in complex shape magnets such as iron parts, copper parts, plastic parts, shells, shafts, etc.

Fully injection molding;

●A complete set of bonded NdFeB rotor and stator assembly can be provided. Strong integration capability.

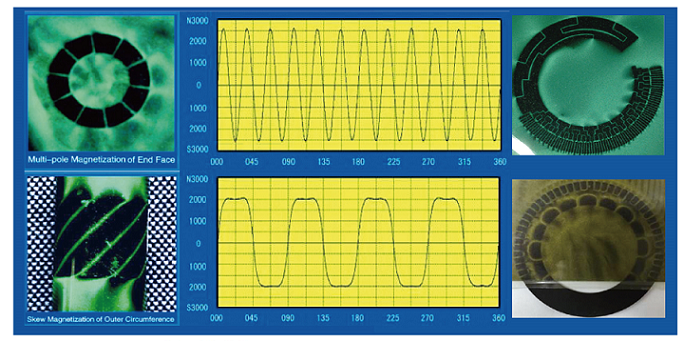

●We have nearly 10 years experience in magnetic circuit design and magnetizing coil design and design

manufacture. The magnetization waveform can be a square wave, a sine wave, or the like.

● Provide a variety of different magnetization, radial magnetization, multi-pole magnetization, radial multi-pole

The magnetization and composite magnetization have stable, uniform and good consistency.

Application field

Bonded Nfell Magnets are mainly used in various small and special motors, such as

Spindle motors (HDD, CD-ROM and DVD), stepper motors, synchronous motors, DC motors and

Brushless motors, etc. Alternative to sintered NdFeB magnets and ferrites. Make the motor assembly

Simpler and more reliable. Reduce costs and improve efficiency.